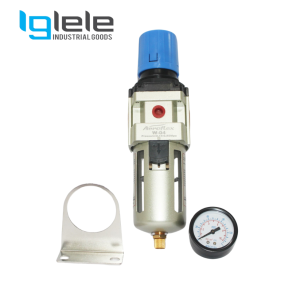

Pneumatic, Pnuematic Frl

Air Regulator Commercial

| Brand | Imported |

|---|---|

| Product Code | R |

| Availability | 48 Hrs |

| Pressure Rating | Upto 18 kg/cm2. |

SKU: R

Availability:

1000 in stock

₹739.00 ₹443.00

Air Regulator Commercial

Features for Air Regulator Commercial:

- Precise Pressure Control: Ensures accurate and stable pressure regulation for optimal performance of pneumatic tools and equipment.

- Durable Construction: Made from high-quality materials such as brass or stainless steel, offering long-lasting durability and resistance to corrosion.

- Wide Pressure Range: Suitable for a broad range of applications, with adjustable pressure settings to match various industrial requirements.

- Compact and Efficient Design: Space-saving design that fits easily into tight workspaces while providing high-efficiency pressure control.

- Easy Adjustment: Features a simple and user-friendly knob or screw mechanism for effortless pressure adjustments.

- Integrated Pressure Gauge: Built-in gauge for real-time pressure monitoring, allowing quick and accurate adjustments.

- High Flow Capacity: Capable of supporting high flow rates, ensuring reliable performance even in high-demand environments.

- Leak-Resistant: Equipped with seals and gaskets to prevent leaks, enhancing safety and reducing maintenance costs.

- Wide Compatibility: Compatible with various air systems, including commercial air compressors, pneumatic tools, and automated machinery.

- Temperature and Vibration Resistance: Designed to withstand fluctuating temperatures and vibrations typically encountered in industrial settings.

- Easy Installation: Simple installation process, compatible with standard fittings and pipelines for quick integration into existing systems.

- Low Maintenance: Requires minimal maintenance, with long-lasting performance and few moving parts to reduce wear and tear.

Applications and Uses:

We specialise in manufacturing a comprehensive range of Iglele tailored to diverse industrial Air Regulator Commercial needs.Reliable performance starts with Air Regulator Commercial Power your operations with confidence.”

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.