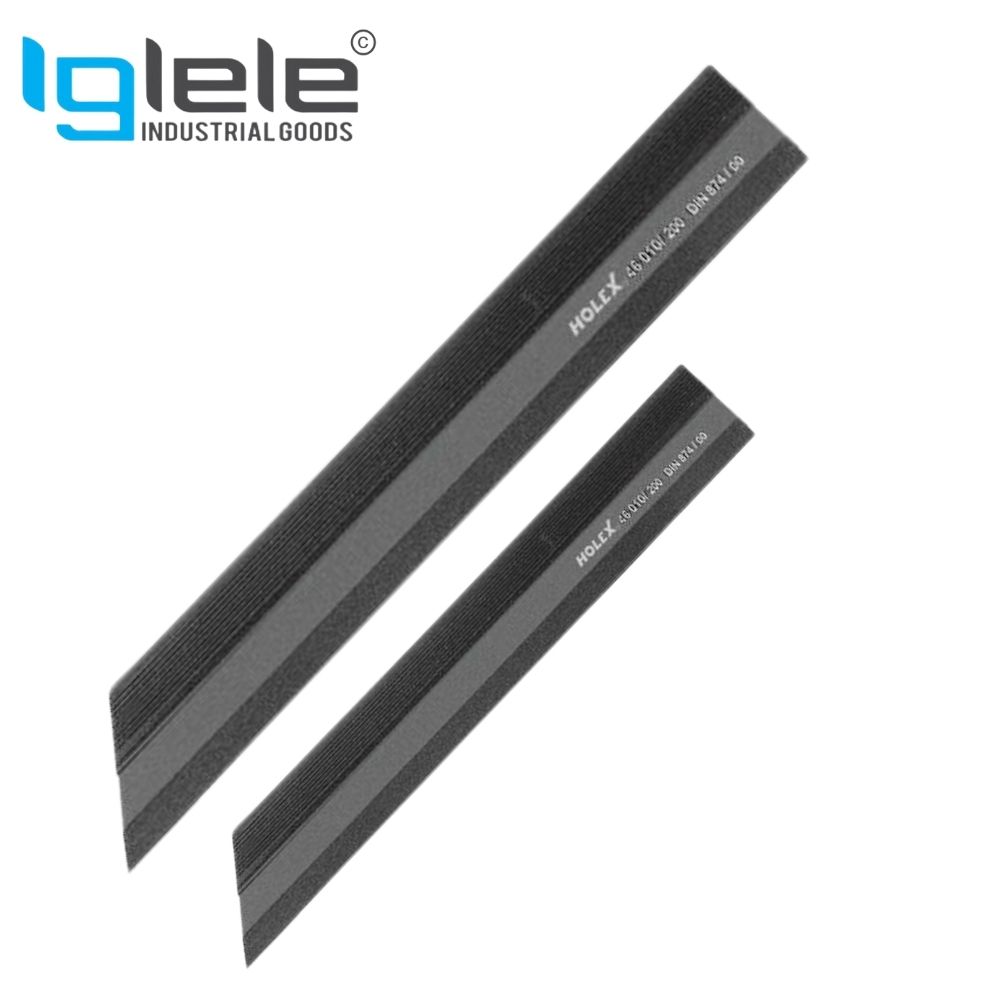

Hardened Precision Straight Edge

| Brand | Make in India |

|---|---|

| Product Code | HEPS |

| Availability | 48 Hrs |

| TYPE | Box Packed |

| CLASS | HEAVY DUTY |

1000 in stock

₹6,067.00 ₹3,640.00

Hardened Precision Straight Edge

Features of Hardened Precision Straight Edge :

-

High-Grade Tool Steel Construction

Made from premium-quality hardened and tempered tool steel for superior durability and wear resistance. -

Hardened & Ground Surface

Precision ground and hardened to ensure long-lasting accuracy and resistance to damage. -

High Straightness Accuracy

Manufactured to meet or exceed IS/BS/DIN standards for straightness, ensuring reliable reference for inspection. -

Beveled or Parallel Edge Design

Available in single-bevel or parallel edge styles for various inspection and marking tasks. -

Corrosion-Resistant Finish

Protected with anti-corrosive treatment to prolong life and maintain performance. -

Precision Ground Edges

Fine ground working edge ensures consistent contact and reliable measurements. -

Available in Multiple Lengths

Offered in various lengths (e.g., 300mm to 2000mm or more) for different applications. -

Chamfered Ends

Smooth, chamfered ends for safe handling and accurate alignment. -

Etched Markings (Optional)

Some models come with finely etched identification or measurement marks for easy identification. -

Inspection Grade Quality

Ideal for use in metrology labs, tool rooms, and quality control departments. -

Stress Relieved Construction

Heat-treated to relieve internal stresses, maintaining straightness over time. -

Suitable for Light Reflection Testing

Perfect for checking flatness by observing light gaps between the surface and the straight edge. -

Sturdy Storage Case (Optional)

Often supplied with a protective wooden or plastic case for safe transport and storage.

Application Of Uses :

-

Flatness and Straightness Inspection

-

Used to check the flatness and straightness of machine beds, surface plates, and other engineering components.

-

-

Surface Alignment Checks

-

Ideal for aligning machinery and equipment during installation or maintenance.

-

-

Tool Room and Metrology Labs

-

Used as a master reference in precision inspection environments.

-

-

Machine Tool Maintenance

-

Essential for evaluating wear and tear or deformation on lathe beds, milling machines, and grinders.

-

-

Blueprint and Layout Work

-

Used for marking out straight lines and edges on workpieces before machining or cutting.

-

-

Assembly Line Inspection

-

Helps in quality control to ensure components meet dimensional standards.

-

-

Surface Plate Calibration

-

Acts as a comparator when checking the accuracy of surface plates.

-

-

Heavy Engineering Applications

-

Used for inspection of large fabricated components where precise straightness is critical.

-

-

Mechanical Workshops and Fabrication Units

-

Useful for general-purpose measurement and marking tasks requiring accuracy.

-

-

Die and Mold Industry

-

Ensures that mold bases and dies are straight and flat before final assembly.

-

Construction and Engineering Projects

-

Helpful in on-site inspection where exact alignment is necessary.

-

Automotive and Aerospace Industry

-

Used for high-precision inspection tasks in critical parts production.

We specialise in supplying a comprehensive range of Iglele Hardened Precision Straight Edge Wireguard tailored to diverse industrial needs. Hardened Precision Straight Edge Wireguard Engineered for durability and performance in your industrial applications.

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.