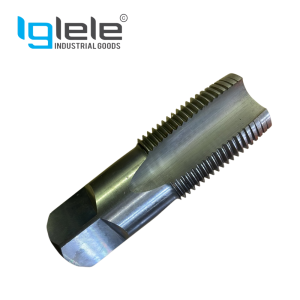

Totem High Performance Taps – Hsse (As Per Is – 6175 / 1977 Bs 949 / 1976) Spirex Gold (Mm)

| Brand | Totem |

|---|---|

| Product Code | TOTHSSESG |

| Availability | 48 Hrs |

| Material | HSS-E |

| CLASS | Haeavy Duty |

| Type | Box Packed |

| MOU | NOS |

100 in stock

₹569.00 ₹342.00

Totem High Performance Taps – Hsse (As Per Is – 6175 / 1977 Bs 949 / 1976) Spirex Gold (Mm)

Features Totem High Performance Taps – Hsse (As Per Is – 6175 / 1977 Bs 949 / 1976) Spirex Gold (Mm)

-

Premium Material: Made from HSSE (High-Speed Steel with Cobalt) for superior hardness, heat resistance, and long-lasting performance.

-

Spirex Gold Coating: Titanium Nitride (TiN) gold coating enhances wear resistance, reduces friction, and extends tool life.

-

Standard Compliance: Manufactured as per IS – 6175 (1977) and BS 949 (1976) ensuring dimensional accuracy and industry-standard threading.

-

Precision Ground Threads: Provides accurate, clean, and consistent metric threads in various engineering materials.

-

High Cutting Efficiency: HSSE material with TiN coating ensures smooth cutting, reduced heat generation, and improved chip evacuation.

-

Durability: Resistant to wear, heat, and deformation, ideal for high-performance industrial applications.

-

Versatile Application: Suitable for mild steel, stainless steel, alloy steels, and other engineering materials.

-

Long Service Life: Outperforms conventional uncoated taps in demanding environments.

-

Professional Grade: Ideal for tool rooms, workshops, and industrial production units requiring precision and reliability.

Applications And Uses :

-

General Engineering & Fabrication – For precision threading in a variety of metals and industrial components.

-

Automobile Industry – Ideal for engine blocks, gear housings, and precision automotive parts.

-

Aerospace & Defense – Suitable for high-strength alloys and critical aerospace components.

-

Machinery & Equipment Manufacturing – Used for threading machine parts, tools, and industrial assemblies.

-

Maintenance & Repair Operations (MRO) – Effective for repairing worn or damaged threads in service workshops.

-

Steel & Alloy Fabrication – Efficient for threading mild steel, stainless steel, and alloy steels.

-

Chemical & Process Industry – Reliable for threading corrosion-resistant and stainless steel components.

-

Construction & Structural Applications – Applicable for threaded fasteners, couplings, and joints.

-

Tool Rooms & Production Units – Essential for precision threading in batch and mass production.

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.