The Ultimate Guide to Nuts and Bolts: Sizes, Types, Screws, and Prices.

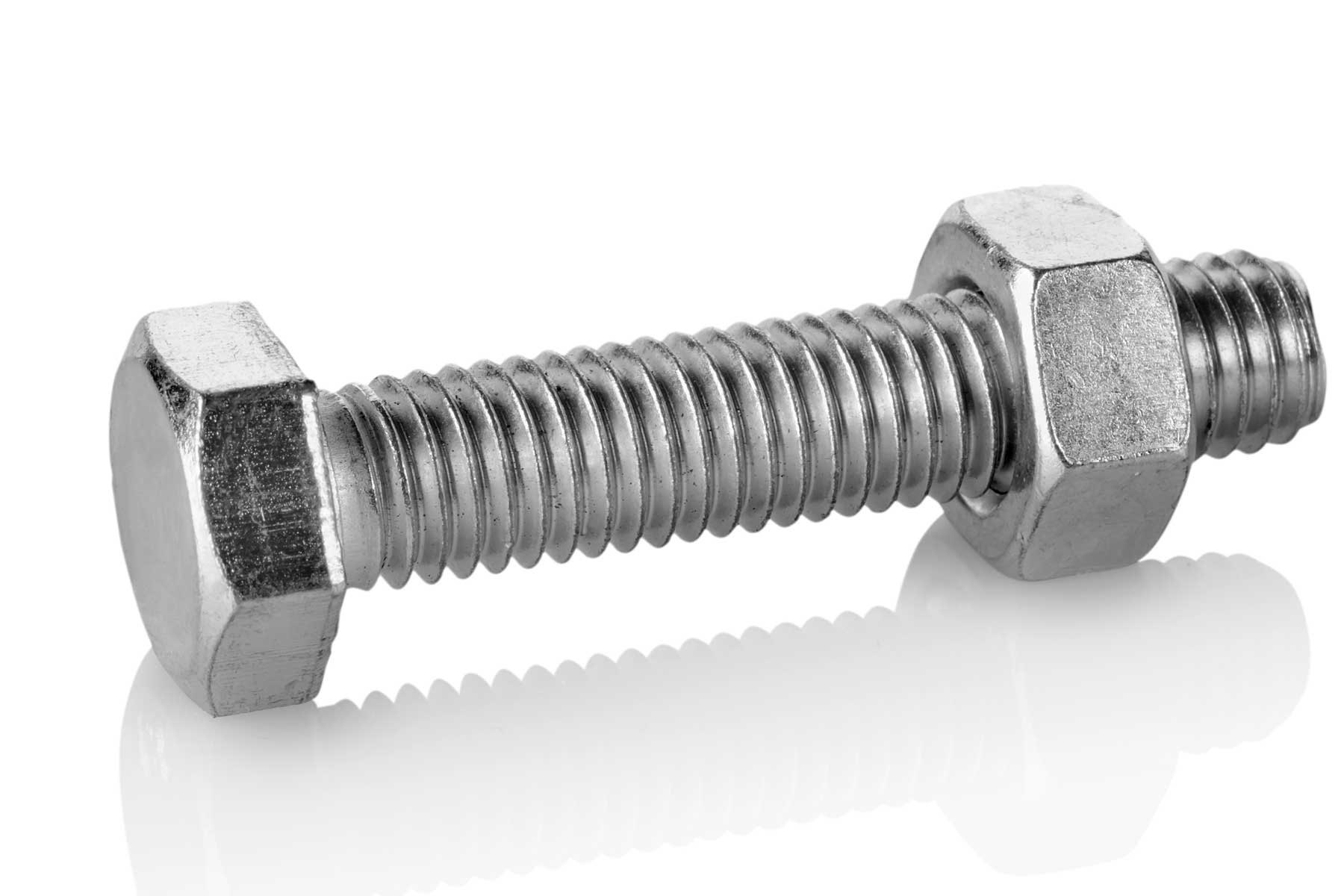

Nuts and bolts are often described as extremely useful equipment that are used to hold together machines, construction trucks, furniture, and other buildings. Fastening devices such as bolts and nuts are extremely useful pieces of equipment in any company that undertakes construction, car repair and even domestic repairs.

From the individual components of various types of nuts and bolts, their sizes, and the function of them, and aware of the price differences, this guide shall provide a general overview of all about nuts and bolts.

1. Nut and Bolt Size:

Knowing the Measurements. When selecting nuts and bolts, it is important to understand the three primary factors that determine their size: diameter, length, and thread pitch. All of these are important in making sure that your fasteners fit perfectly in your project.

A. Diameter:

The diameter is the bolt’s thickness. In metric, the size is usually expressed as M6, M8, M10, etc. For example, M6 means that the bolt has a 6mm diameter. The diameter will inform you of how large the hole should be in the material you are attaching.

Common sizes and their uses:

- M4: Small screws for light-duty tasks like electronics and toys.

- M6: Standard size for furniture assembly and light construction.

- M8: Used for bicycles, small engines, and vehicles.

- M10: Suitable for automotive parts, machinery, and structural applications.

- M12: Heavy-duty bolts for large machinery or steel buildings.

b. Length:

The bolt length is the distance from the thread bottom to the head underside. The length should be sufficient to travel through the materials you are going to join. The material thickness will assist in determining the appropriate bolt length. For instance, a 20 mm-thick plate might need a bolt that’s 30mm or more.

c. Thread Pitch:

Pitch of threads is the distance between threads on a bolt. The shorter the pitch, the more threads per inch, which produces a tighter fit. Coarse threads allow for faster assembly and are generally stronger in most applications.

Tip: Always ensure the bolt and nut have matching diameters and thread pitches to ensure a secure fit.

2. Types of Nuts and Bolts: Which One Should You Choose?

Nuts and bolts come in a wide variety of shapes and sizes, each designed for specific applications. It’s crucial to choose the right type for your project to ensure safety, efficiency, and durability.

a. Types of Bolts:

- Hex Bolt: The most common bolt, featuring a hexagonal head. It’s widely used in machinery, automotive, and construction industries due to its ease of use with a wrench.

- Carriage Bolt: Features a round head with a square section under the head, which prevents the bolt from turning once it’s inserted. Often used for fastening wood.

- Eye Bolt: Has a loop at one end, ideal for lifting objects or tying ropes.

- U-Bolt: Shaped like a “U,” these bolts are threaded on both ends and are typically used to secure pipes or rods to flat surfaces.

- Anchor Bolt: Embedded into concrete, anchor bolts are used to secure heavy structures and machinery.

b. Types of Nuts:

- Hex Nut: The standard six-sided nut, commonly used with hex bolts.

- Wing Nut: Features “wings” for easy hand tightening. It’s useful when quick assembly or disassembly is required.

- Lock Nut: Has a nylon insert or special threads to prevent loosening from vibrations. Often used in machinery and automotive applications.

- Cap Nut: A domed nut that covers the end of the bolt. Used for safety and aesthetic purposes.

Flange Nut: Has a wide base that helps distribute pressure evenly and eliminates the need for a washer.

3. Nut and Bolt Prices: What Affects the Cost?

Nut and bolt prices can vary significantly based on factors like material, size, type, and quantity. Understanding the cost structure helps you make informed purchasing decisions.

Factors Affecting Price:

- Material: Stainless steel bolts are more expensive than mild steel bolts due to their corrosion resistance.

- Size: Larger bolts or those with special designs (like U-bolts) typically cost more.

- Type: Speciality bolts, such as eye bolts or anchor bolts, are more expensive than standard hex bolts.

- Quantity: Bulk purchases often come at a discount.Approximate Prices (India 2024)

| Item | Size | Price per Piece |

|---|---|---|

| Mild Steel Hex Bolt | M6 x 20 mm | ₹2 – ₹5 |

| Stainless Steel Bolt | M8 x 40 mm | ₹10 – ₹20 |

| Carriage Bolt | M10 x 50 mm | ₹12 – ₹30 |

| Eye Bolt | M12 | ₹40 – ₹90 |

| Wing Nut | M6 | ₹5 – ₹10 |

| Flat Washer | M6 | ₹0.50 – ₹2 |

| Lock Nut (Nylon) | M8 | ₹3 – ₹8 |

Note: Prices can fluctuate based on brand, region, and retailer.

4. Benefits of Using Nuts and Bolts

Nuts and bolts may seem like simple tools, but they provide many important benefits in construction, repair, and other applications. Below are some of the key advantages of using these fasteners:

a. Strength and Durability

- Nuts and bolts are highly strong and can withstand significant tension, compression, and shear forces. This makes them ideal for use in heavy machinery, vehicles, and industrial applications.

- They are durable and resist wear and tear, making them suitable for long-lasting and reliable fastening.

b. Versatility

- Nuts and bolts come in various types and sizes, making them suitable for almost any project.

- They can fasten metal, wood, plastic, and other materials, which gives them immense versatility.

c. Reusability

- Unlike some other fasteners (e.g., nails), nuts and bolts can be removed and reused multiple times without losing their effectiveness. This makes them cost-effective, especially for projects that may require disassembly.

d. Ease of Installation

- Nuts and bolts are easy to install and tighten using standard tools like wrenches and screwdrivers. The process is straightforward, reducing the time required for assembly or repair.

- Many nuts and bolts also come in pre-threaded designs, making installation easier and faster.

e. High Security

- Lock nuts, spring washers, and other security washers ensure that nuts and bolts stay tight and secure, even under vibration or heavy stress. This makes them ideal for critical applications in machinery, automotive, and other engineering fields.

f. Cost-Effectiveness

Nuts and bolts are generally inexpensive, especially when.

Conclusion

Nuts and bolts may appear to be simple mechanical components, but they are fundamental to the stability, safety, and functionality of virtually every machine, structure, and device. Understanding the size, type, and purpose of each nut and bolt is essential to ensuring that your projects are strong, reliable, and durable. The use of washers enhances the performance of these fasteners, preventing loosening and distributing pressure more effectively.

From understanding the different types of bolts, like hex bolts, carriage bolts, and U-bolts, to the various kinds of nuts, such as lock nuts and wing nuts, the wide variety of fasteners available ensures that there is a solution for every need. When combined with the right washers, these fasteners can handle heavy-duty applications, reduce wear and tear, and increase longevity.