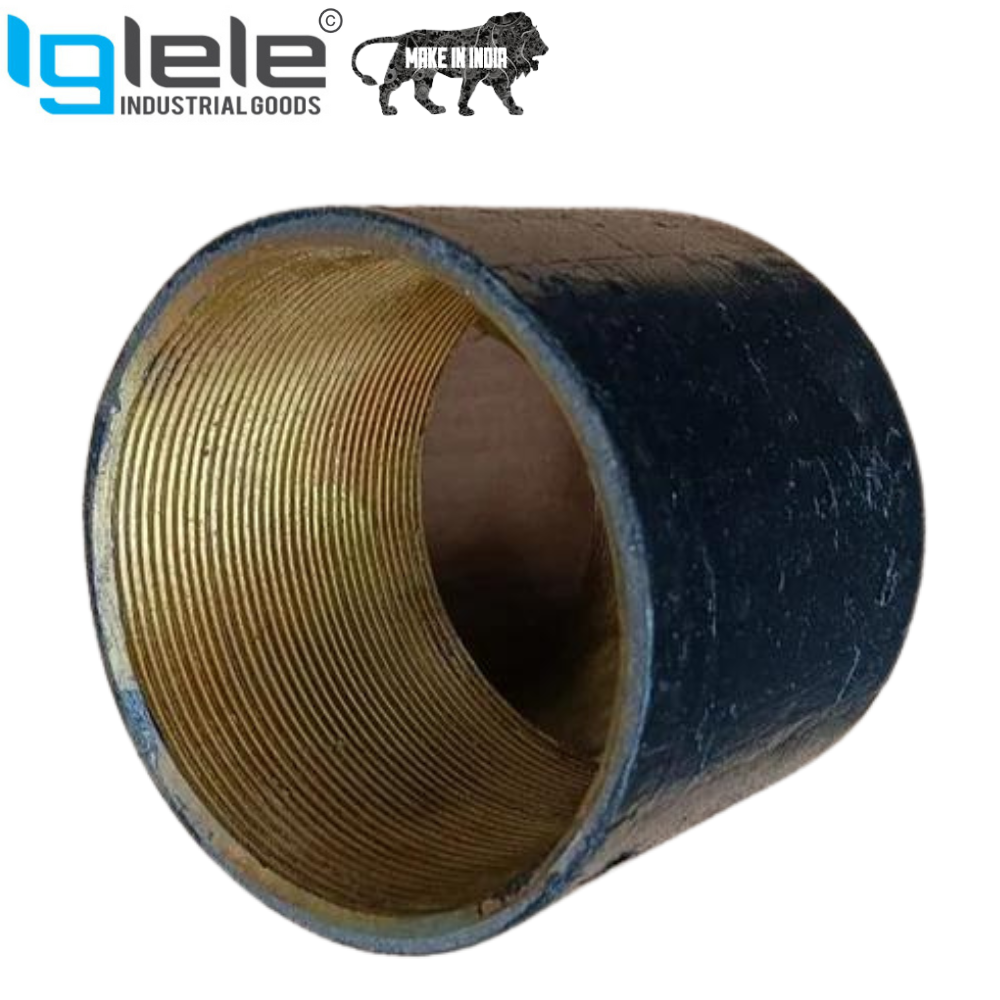

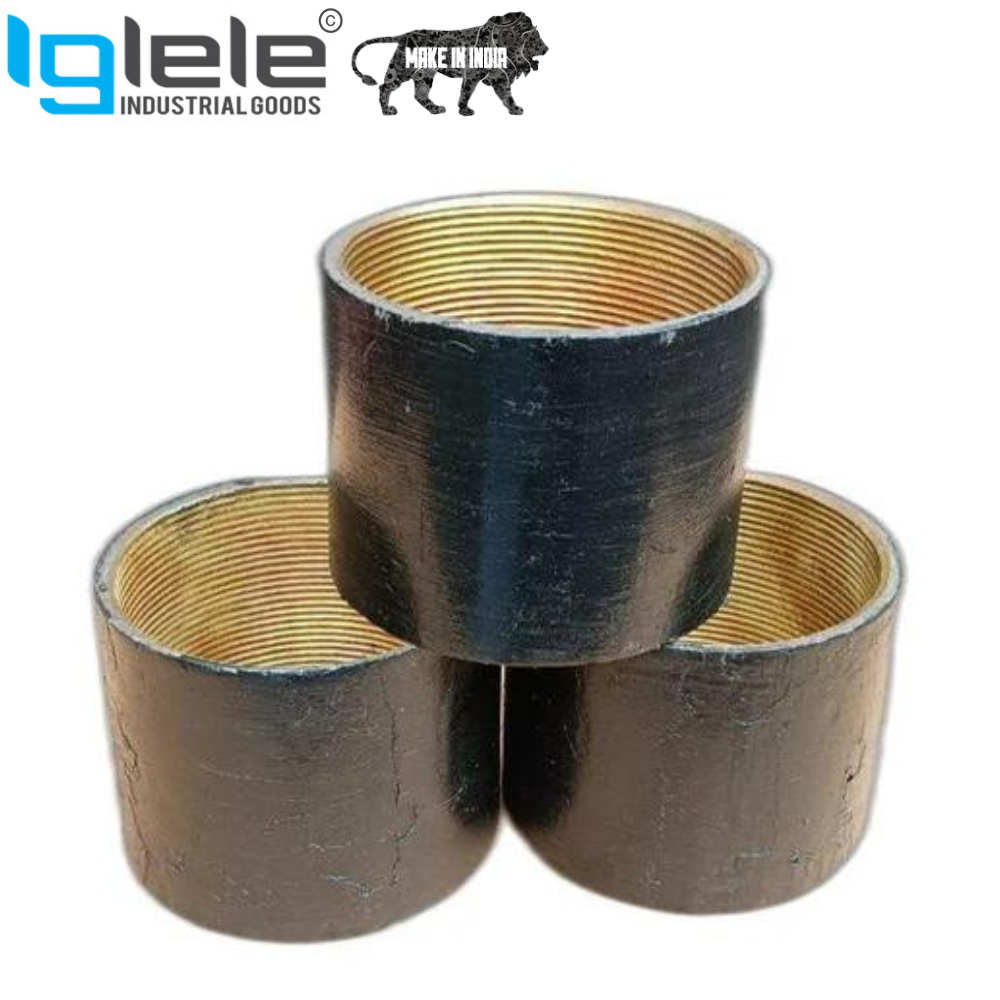

MS Cap Female Forging

| Brand | Make in India |

|---|---|

| Product Code | MSFECF |

| Availability | 48 Hrs |

| Thread | As Per BSP Thread |

| MATERIAL | M.S Mild Steel |

| Standard/Pressure Rating | Upto 0-3000PSI. |

| Class | Heavy Duty Suitable For Welding. |

1000 in stock

₹35.00 ₹19.00

IGLELE MS Forging Screwed Fittings.

At Iglele, we take pride in being your go-to supplier for the finest MS forged fittings, meticulously manufactured and made in India. Our commitment is to provide customers with unparalleled quality at the most affordable rates. We specialise in delivering a range of MS forged fittings that not only meet but exceed industry standards.

Our products showcase the precision and craftsmanship synonymous with Indian manufacturing excellence. By collaborating with leading manufacturers in the country, we ensure that each fitting reflects the durability and reliability you expect. What sets us apart is our dedication to making these high-quality products accessible to you at the most competitive prices.

Discover the perfect balance of quality and affordability with Iglele. Experience the reliability of Indian-made MS forged fittings, where every purchase represents a commitment to excellence without breaking the bank. Choose Iglele – your trusted partner for securing the best in MS forged fittings, proudly made and supplied from India.

Types of MS Forging Screwed Fittings.

- Forged MS Elbows: These fittings provide changes in direction within piping systems, enabling redirection of flow or accommodating bends without compromising flow efficiency.

- Forged MS Tees: Tees branch out a piping line into two separate directions, facilitating distribution or diversion of fluid flow within the system.

- Forged MS Couplings: Used to connect two threaded ends of piping or fittings, ensuring a secure and leak-free joint.

- Forged MS Unions: These fittings offer a detachable connection between two pipes or fittings, allowing for disassembly and maintenance of the system without altering the pipeline.

- Forged MS Caps: Used to seal the ends of piping or fittings, preventing leakage and protecting the system from debris or contamination.

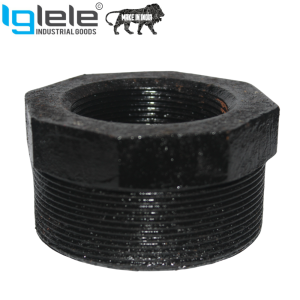

- Forged MS Bushings: These fittings are employed to reduce or connect pipes of varying diameters, facilitating smooth flow within the piping system.

Applications and Uses

- Piping Systems: These fittings are extensively used in piping systems across industries, including oil and gas, chemical processing, water treatment, and more. They facilitate fluid flow, direction changes, and connections within the piping network.

- Industrial Machinery: Iglele MS forging screwed fittings are employed in industrial machinery, such as manufacturing equipment, presses, and processing units, ensuring proper fluid control and transfer.

- Construction Sector: In construction projects, these fittings find use in plumbing, HVAC systems, and infrastructure development, ensuring efficient fluid handling and distribution.

- Oil and Gas Industry: These fittings are crucial in the oil and gas sector for various applications, including pipelines, refineries, drilling rigs, and extraction equipment, where they endure high-pressure and demanding conditions.

- Chemical Processing Plants: In chemical industries, Iglele MS forging screwed fittings are utilized for their resistance to corrosion, handling different chemicals, and maintaining fluid control within the processes.

- Water and Wastewater Treatment: They are employed in water treatment plants and wastewater management facilities for fluid transfer, directing flow, and maintaining system integrity.

- Automotive and Manufacturing: Used in hydraulic systems within automotive manufacturing, heavy machinery, and other manufacturing processes requiring controlled fluid flow and direction.

Pressure Considerations:

- Fitting Type: Different types of fittings have varying pressure ratings based on their design and intended use. For instance, tees or elbows might have different pressure ratings compared to couplings or caps.

- Material Quality: The quality and grade of the mild steel used in the fittings influence their pressure handling capacity. Higher-grade steel typically offers better pressure resistance.

- Thread Integrity: The threading on the fittings and their connections play a critical role in maintaining pressure integrity. Properly sealed and tightened threads are essential to prevent leaks under pressure.

- Wall Thickness: The thickness of the material used in the fittings affects their ability to withstand pressure. Thicker walls generally offer higher pressure ratings.

- Application Requirements: Different industries and applications have varying pressure requirements. Fittings used in high-pressure hydraulic systems need higher pressure ratings compared to those used in lower-pressure plumbing systems.

- Adherence to Standards: Iglele’s MS forging screwed fittings are likely designed and manufactured following industry standards such as ASME (American Society of Mechanical Engineers) or ASTM (American Society for Testing and Materials), ensuring that they meet specific pressure and safety requirements.

We specialise in manufacturing a comprehensive range of Iglele MS Forging Screwed Fittings tailored to diverse industrial needs. From flare fittings to Pipe fittings and more, our offerings cover all types of forging connections. For bulk orders or custom requirements, customers can directly reach out to us for seamless solutions tailored to their specific applications.

No guarantee for Grade Purity, breakage or thickness leakage for commercial and light duty Fittings. Pressure rating for each fittings varies for different sizes. No guarantee will be provided for the same. The sizes,images and dimensions may vary according to the different range of products. Please Confirm the exact details before placing the order. Thickness may vary according to different size and quality. Contact us for in depth technical details. T.C will be provided on special request for heavy duty fittings only. We recommend you to order heavy duty filings where highest reliability is required. No refund will be made for the wrong size order.

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.