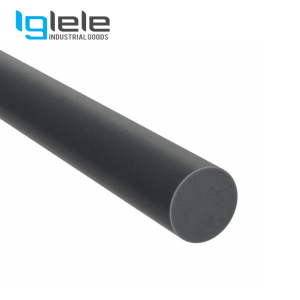

Packing rubber cord, also known simply as rubber cord or rubber packing cord, is a versatile sealing material commonly used in various applications where a flexible and compressible seal is required. It consists of a cylindrical or round cord made from rubber or elastomeric materials, which can be easily manipulated and compressed to form a seal between two mating surfaces.

Here’s a detailed description of packing rubber cord:

1. Material:

- Packing rubber cord is typically made from synthetic rubber compounds such as neoprene, EPDM (Ethylene Propylene Diene Monomer), silicone, nitrile, or Viton. These materials offer excellent flexibility, resilience, and chemical resistance, making them suitable for a wide range of sealing applications.

2. Construction:

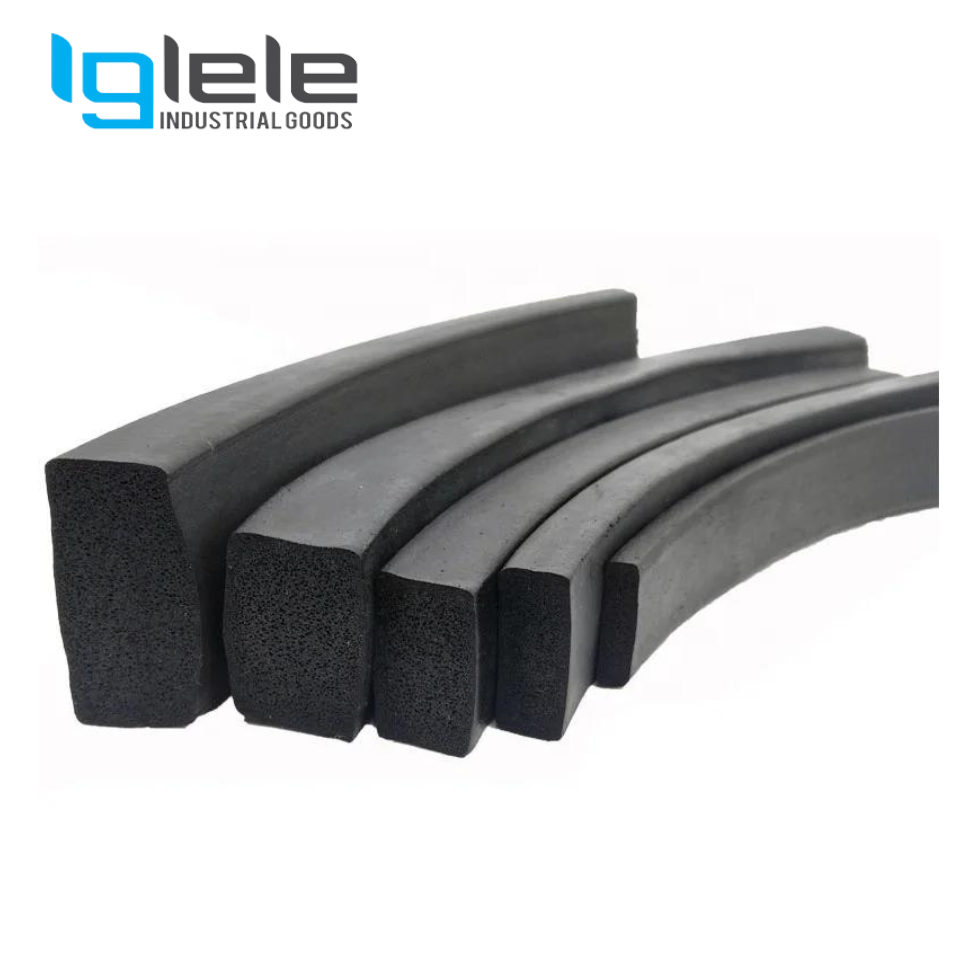

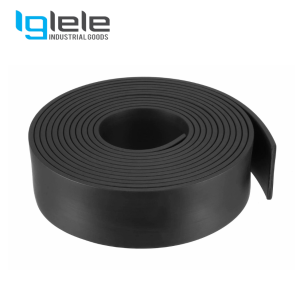

- The rubber cord is manufactured in various diameters and lengths to accommodate different sealing requirements. It is typically supplied in coils or spools, allowing for easy storage and dispensing. The cord’s cross-sectional shape can vary from circular to square or rectangular, depending on the application needs.

3. Properties

-

- Flexibility: Packing rubber cord is highly flexible, allowing it to conform to irregular surfaces and contours effectively.

- Compressibility: Rubber cord can be easily compressed or deformed to create a tight seal between mating surfaces. Its compressibility allows it to fill gaps and irregularities, providing a reliable seal even in challenging environments.

- Chemical Resistance: Depending on the specific rubber material used, packing rubber cord can offer resistance to various chemicals, oils, solvents, and environmental factors, ensuring long-term durability and performance.

- Temperature Resistance: Rubber cord materials are often formulated to withstand a wide range of temperatures, from extreme cold to high heat, making them suitable for use in diverse industrial applications.

- Weather Resistance: Many rubber cord materials exhibit excellent weather resistance, including resistance to UV radiation, ozone, and moisture, making them suitable for outdoor and exposed applications.

4. Applications:

-

- Sealing: Packing rubber cord is commonly used for sealing applications in industries such as plumbing, HVAC (heating, ventilation, and air conditioning), automotive, construction, and manufacturing. It can be used to seal joints, flanges, valves, doors, windows, and various other components.

- Gasketing: Rubber cord can be compressed into gasket shapes to create custom seals for specific applications, providing a cost-effective and versatile sealing solution.

- Insulation: In addition to sealing, rubber cord can also be used for insulation purposes, such as sealing gaps around doors and windows to improve energy efficiency and soundproofing.

5. Installation:

-

- Packing rubber cord is typically installed by manually inserting it into the gap or groove between mating surfaces, ensuring that it is compressed sufficiently to form a tight seal.

- Depending on the application, adhesive or sealant may be applied to enhance the sealing performance of the rubber cord.

In summary, packing rubber cord is a flexible, compressible, and durable sealing material used in a wide range of industrial and commercial applications. Its versatility, chemical resistance, and ease of installation make it an essential component for creating effective seals in various environments.

There are no reviews yet.