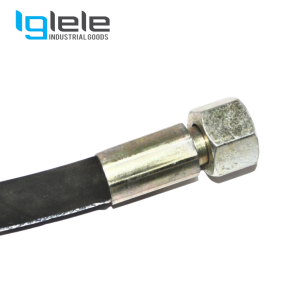

Hydraulic Hose Pipes R2

Hydraulic Minimize Hose

| Brand | Make in India |

|---|---|

| Product Code | HYDMINHS |

| Availability | 48 Hrs |

| Material | Black Synthetic rubber oil & Water MS |

SKU: HYDMINHS

Availability:

1000 in stock

₹960.00 ₹672.00

Hydraulic Minimize Hose

Type :

1. Reinforced Rubber Hoses

- Description: Made from synthetic rubber with one or more layers of reinforcement (such as steel wire or fabric).

- Applications: Suitable for general hydraulic applications with moderate pressures.

- Advantages: Flexible, resistant to abrasion, and relatively cost-effective.

- Considerations: May have limitations in extreme temperature or high-pressure conditions.

2. Thermoplastic Hoses

- Description: Constructed from thermoplastic materials (like nylon or polyester) with synthetic rubber or elastomeric linings.

- Applications: Ideal for applications requiring high flexibility and resistance to chemicals, abrasion, and high pressures.

- Advantages: Lightweight, durable, and offers excellent resistance to external factors.

- Considerations: Can be less flexible at lower temperatures compared to rubber hoses.

3. Metallic Hoses

- Description: Made from stainless steel or other metals, often braided or convoluted.

- Applications: Best for high-temperature or high-pressure applications, and in environments where chemical resistance is needed.

- Advantages: Excellent strength, durability, and resistance to high temperatures and pressures.

- Considerations: Typically less flexible than rubber or thermoplastic hoses.

4. Double Steel Wire Braid Hoses

- Description: Features two layers of steel wire braid for enhanced strength and pressure handling.

- Applications: Used in high-pressure hydraulic systems where additional reinforcement is required.

- Advantages: Very high pressure and burst strength, suitable for demanding applications.

- Considerations: Less flexible, which can make installation and maneuverability more challenging.

5. High-Pressure Thermoplastic Hoses

- Description: These hoses use high-strength thermoplastic materials and are designed to handle very high pressures.

- Applications: Suitable for ultra-high-pressure hydraulic applications.

- Advantages: Provides high burst and working pressures, along with resistance to harsh chemicals and abrasion.

- Considerations: Can be more expensive and may have reduced flexibility compared to lower-pressure hoses.

6. Fire-Resistant Hoses

- Description: Designed to withstand exposure to flames and high temperatures without losing integrity.

- Applications: Used in environments where there is a high risk of fire or extreme heat, such as in industrial and aerospace applications.

- Advantages: Enhanced safety in hazardous conditions.

- Considerations: Usually more expensive and may be less flexible.

Key Considerations for Minimizing Hose Issues:

- Pressure Ratings: Always select a hose with a pressure rating higher than the maximum pressure in your system.

- Temperature Range: Ensure the hose can handle the operating temperature of your system.

- Chemical Compatibility: Verify that the hose material is compatible with the fluids it will transport.

- Flexibility and Bend Radius: Choose a hose that offers the required flexibility and has an appropriate bend radius for your installation.

- Abrasion Resistance: For applications where hoses are exposed to wear and tear, select hoses with high abrasion resistance.

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.