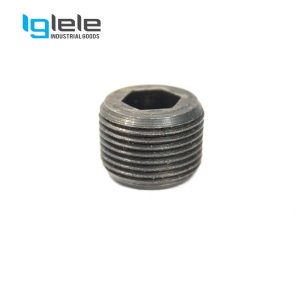

MS Hexagonal Hydraulic Threaded fittings

HDYRAULIC MINIMIZE COUPLINGS

SKU: HYDMINHC

Availability:

1000 in stock

₹67.00 ₹27.00

| Thread BSP | 1/4''BSP, 1/8''BSP |

|---|

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.